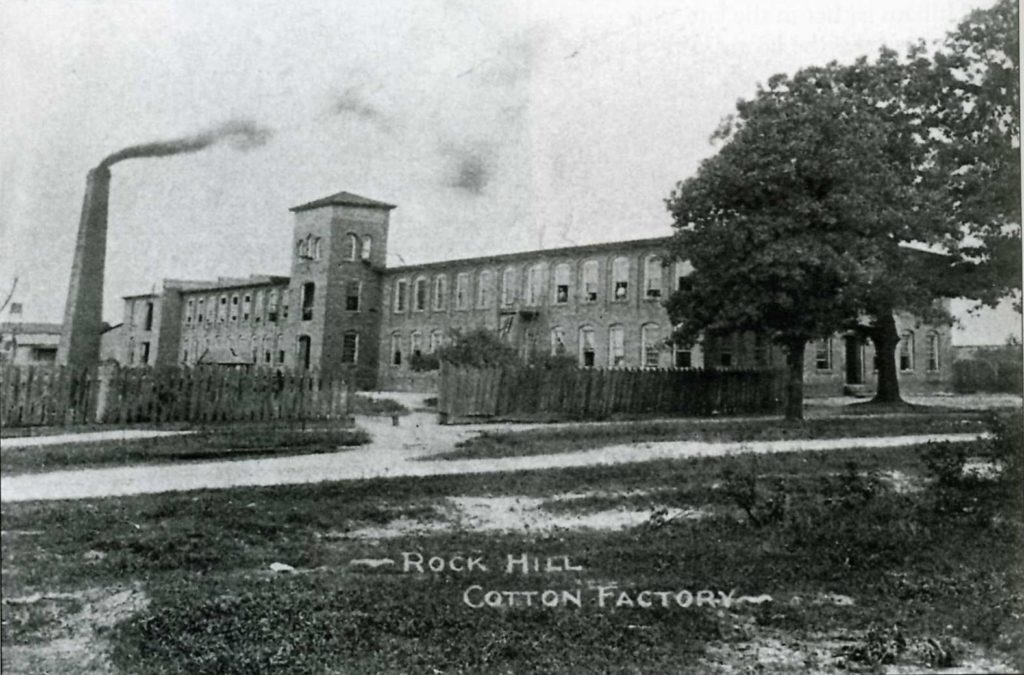

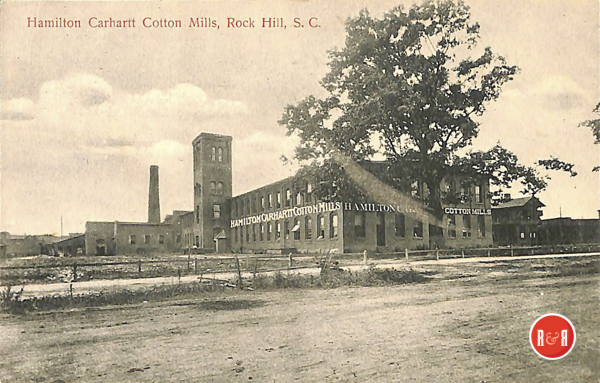

“Rock Hill’s first textile mill, ca. 1880.”

City Directories and History: The historic Rock Hill Cotton Factory was Rock Hill’s first cotton mill and one of the first in this section of South Carolina.

The Rock Hill Herald reported on June 3, 1880 – “Mr. R. H. Morse, who is putting up the buildings for A. Friedheim and Bro., and for Dr. T.C. Robertson, also is the contractor for the brickwork on the RH Cotton Factory and he will begin work there soon. He is also the contractor for the cotton factory in Charlotte.”

Later the paper added on May 27th – “The plans for the Rock Hill Cotton Factory may be seen by the public at the store of W.L. Roddey and Company. The building will be 218 ft long and 70 ft wide. There will also be an engine room 75 ft – 30 ft.”

On Aug. 19th (1880), an advertisement in the Herald read: “One thousand cords of wood wanted for the RH Cotton Factory, apply to A.E. Hutchison, Pres.”

The Herald reported on Oct. 14, 1880 – “The brickwork for the RH Cotton Factory is almost completed and the roofing will now go on. The engines should arrive any day.” On Oct. 28 the paper reported – ” the engine and boilers for the RH Cotton Factory have arrived. On Nov. 11 the paper states, “Pres. A.E. Hutchison reports that the cotton factory building is nearing completion. The roof is of iron and should be completed this week. Work on the smoke stack is continuing and it will be 85 ft tall. The building is 250-71 ft and has two stories, surmounted by a cupula.”

The erection of The Rock Hill Cotton Factory put the little town on the industrial map, not only demanding the attention of the outside world, but opening the eyes of its own people to the wonderful possibilities of industrial development. Said the Yorkville Enquirer in 1884 of Rock Hill: “This point has been recognized for the past six years as one of the most important cotton markets on the Charlotte, Columbia and Augusta Railroad, and in the price it pays yields to neither terminus. During the time above mentioned, Rock Hill has shipped to New York and other markets about 85,000 bales of cotton. For the year ending September 1, 1888, her receipts from the country by wagons, amount to 14,169 bales against 13,744 the year before. The factory now in operation consumes something over 2,500 bales annually …. ” The building of the first cotton mill, moreover, was an object lesson to the townspeople. It was a venture they wanted to see repeated. As other mills were built, The Rock Hill Cotton Factory became known as “The Old Mill,” and, after numerous reorganizations and changes of name, it still operates as a unit of the Gold-Tex Fabrics Corporation. (Information from: The City Without Cobwebs – Douglas S. Brown, 1953)

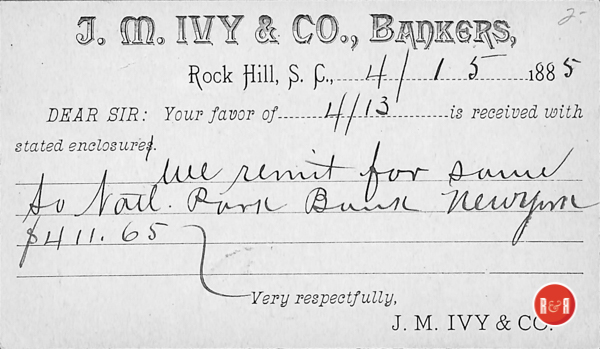

The Rock Hill Herald reported on March 4, 1880 – “A meeting was held last Saturday of several men who discussed establishing a cotton factory at Rock Hill. A committee composed of: A.E. Hutchison, W.L. Roddey, and J.M. Ivy will visit a number of factories now in operation.”

On April 22nd 1880 the Herald reported, “Capt. A.E. Hutchison has returned from Providence RI where he had gone in the interest of the RH Cotton Factory, of which he is President. He contracted for the machinery for 3,000 spindles to be delivered in Nov., from the Franklin Foundry and Machine Shop in Providence. The factory building will be located near the Depot. They expect to employee about 60 operatives for which cabins will be built.”

On April 29, 1880 A.E. Hutchison recently attended the annual stock holders meeting of the Graniteville Manufacturing Company. Capt. Hutchison owns a large number of shares. The Pres. of the Company is Mr. Hickman. The Company has improved the factory, paid regular dividends, and the Vaucluse Factory has been built at a cost of $347,000., with 10,000 spindles.”

The Herald reported on July 15, 1880, That the cotton factory will soon be a fact. “….. the eye will look with delight upon the massive structure, whose walls will echo for generations to come with the merry music of spindles.” The factory is located near the depot. The work of digging out the foundations began last week and has been finished and the work on the building itself has begun. We expect manufacturing operations to being about Nov. 1st.”

The Herald reported on March 17, 1881 – ROCK HILL COTTON FACTORY

The Rock Hill Herald reported on March 17, 1881: Mr. J. E. Murphy of Providence, RI is here putting up the speeders for the factory (Rock Hill Cotton Factory). The Rock Hill Herald reported on May 12, 1881: The first bale of cotton for the Rock Hill Cotton Factory was bought on Monday from Mr. Elisha Warren at 10 cents. The Rock Hill Herald reported on May 19, 1881: May 11 will be remembered as an important day in Rock Hill history, as the first thread was spun at the Rock Hill Cotton factory. The Rock Hill Herald reported on May 26, 1881: It is pleasing to see the Rock Hill Cotton Factory in operation. The machinery is working well and the number of spindles in increasing, with 3,120 now in operation. The number of employees is now 40, including men, women and children. They are for the most part from North Carolina. Mr. J. R. Neisler, formerly of Charlotte, is the superintendent. On March 24, 1881 the Herald also stated – “Mr. A.D. Holler is putting up several cottages for the factory employees.”The Rock Hill Herald reported on June 9, 1881: The annual meeting of the Rock Hill Factory Company was held at Roddey’s Hall on May 31. Capt. Allen Jones chaired the meeting and D. Hutchison, Esq. acted as Secretary. A summary of the activities for the year was provided. The following companies provided machinery for the mill: cards, draw frames, stubbers, and speeders were from the shops of Franklin Foundry of providence, RI, pickers and loppers from the Rison Machine Company in Lowell, MA, the automatic cut-off engine of 150 hp from William Wright of Newburgh, NY, two boilers from Frick & Co. of Waynesboro, PA., the brick work was done by R. H. Morse, and the woodwork by A. D. Holler. The brick work was completed by about the end of 1880 and the wood work around March 31, 1881. The mill is now in operation. The mill is two stories and 215 feet by 68 feet. The smoke stack is 82 feet high. The engine room is also two stories and is 20 x 30 feet. There are nine tenement houses of three rooms each. The mill is on a six acre site on the north side of the railroad. The mill also owns 400 acres of heavily wooded land three miles from Rock Hill to supply wood for the boilers. The total cost was $99,281.65. The board members at the meeting were A. E. Hutchison, J. L. Middleton, J. M. Ivy, W. L. Roddey, J. R. London, W. B. Fewell, and A. H. White.

From the Rock Hill Herald, June 8, 1882 – On the 30th of May the stockholders of the Rock Hill Manufacturing Company held their annual meeting at this place. From the report of the President of the company, A. E. Hutchison, we learn that operations of the factory was commenced on the 12th of May, 1881, with only a few hundred spindles, and that the number was gradually added to until by the first of September following the mill had a total of 6,240 spindles in operation. Up to the date of the report (May 1st) the Company had purchased and worked up 1,332 bales of cotton, averaging 449 pounds per bale, the total cost of which was $62,373.87. It has sold 1,495 bales, or 479,708 pounds, of No. 20 yearn. The total cost of buildings and machinery on hand up to May 1st was $124,000. The company has paid out in wages to hands and operatives $13,462.40. The report shows nineteen tenement houses for operatives, four of which have six rooms each, four 3 rooms each, ten 2 rooms each and one 8 rooms. (The Herald reported there are now 19 houses for operatives on this date.)

At present the mill has 7,904 spindles in operation – 1,664 having been put in operation since May 1st of this year – and there is room to add 5,096. Since the recent addition of spindles, there has of course been a considerable increase of yarn, and last week, as a result of the week’s work, the Company shipped forty-four bales. The results of the operations of the mill to May 1st show a very satisfactory profit to the stock holders, who believe that the second year’s operations will show a much larger per cent, the machinery being in good working order now and everything moving on smoothly and nicely.

The YK Enquirer stated on Feb. 15, 1883 – “Coal is now being used as fuel at the RH Cotton Factory. The owners believe it is superior to wood as a fuel.”

The Herald reported on May 31, 1883 – The Annual Meeting of Stockholders – “The company had a net profit of 5% during the year. The board discussed adding additional machinery for making twisted yarn.”

The Herald reported on Sept. 27, 1883 – “Mr. Fellows of the Fellows Manufacturing Co., of Richmond Va., has been in Rock Hill for a week. He has a contract for installing a steam heater and feeder and an automatic steam trap at the Rock Hill Cotton Factory.”

The Herald Nov. 8, 1883 reported on an accident at the RH Cotton Factory occurring when a connecting rod of the engine broke, leaving other parts to also fail. The broken parts have been sent North and repairs will take about a month. The board is considering adding a second engine in case of future accidents.” On the 23rd the paper further reported – “The new Westinghouse engine has arrived and will be installed in a few days. The repairs for the broken engine have been completed and the parts will be returned within two weeks.”

The Herald reported on Oct. 29, 1885 – “The RH Cotton Factory has let the contract for the building of a brick warehouse for storing cotton. The building will be 80-100 ft, Mr. Holler has the contract.”

On Nov. 19, 1885 the Yorkville Enquirer reported – “The RH Cotton Factory is building a large brick warehouse to store cotton. It is intended to be as fire proof as possible.”

The YV Enquirer reported on May 14, 1890 – “The residence of the cottages of the Rock Hill Cotton Mill were upset recently by the appearance of a mad dog. Two children of Mr. W.C. Martin and one child of Mr. H. Macus were bitten. All three children are now in Charlotte for treatment.”

The Rock Hill Herald reported on Oct. 13, 1881 – “The RH Cotton Factory has bought 7.5 acres of land adjoining the factory from Mr. Mac Steele and will erect a number of cottages for operatives. When six houses have been completed the labor force will be increased. In the six months that is has operated the factory has shipped 559 bales of thread worth about $34,000.”

The Herald reported on Oct. 25, 1888 – “Mr. J. Edgar Poag has bought the vacant lot near the cotton factory on which Mr. John Ratteree’s Stables formerly stood and has sold the lot to the factory.”

The YV Enquirer reported on Oct. 11 and Nov. 1, 1893 – “Rock Hill is experiencing an economic depression due to the cotton market. The Standard Mill has cut wages by 20%. The Rock Hill Cotton Factory has only run 1/3 of the time for the last three months, and there is no expectation of immediate improvement. If it does not operate more regularly, a number of employees will need to leave.”

The Yorkville Enquirer reported on March 14, 1894 – “Two car loads of 200 new looms to be used at the Rock Hill Cotton Mill have arrived and will be used in manufacturing plain white goods. New hands will be needed to operate these looms.”

The Herald reported on Jan. 21, 1899 – “The RH Cotton Factory has not operated since last summer. The company has asked for the appointment of a receiver to take charge assets and distributed them to creditors. The company is insolvent and owes Mr. A.E. Hutchison large sums, which he advanced from his private means. Total debts total $115,284. Creditors also include several NY Companies, Louis Rhea, Mary E. White, Peoples National Bank of Charleston, A.H. White, and numerous banks all over S.C. and locally.”

Courtesy of the AFLLC Collection – 2017

From the Rock Hill Herald, August 2, 1899: The Rock Hill Cotton Factory, the oldest manufacturing plant in our city, which was placed in the hands of receiver R. Lee Kerr during the last year, was sold at public auction in Rock Hill on Thursday of last week by the receiver, and was bought by Dr. J. H. McAden of Charlotte for $31,000, that being the upset figure placed upon the property by the court. After the sale, we are reliably informed, the bid was transferred to Rock Hill parties who have applied for a charter for the Crescent Cotton Mills of Rock Hill. The persons making the application are Messrs. A. H. White and W. C. Hutchison. The capital stock of the company will be $50,000, divided into 5,000 shares of a par value of $100 each. We have some information as to the prospective officers, but are not authorized to make this public for the present.

The plans for the Crescent Company will be to operate the mill at as early a date as possible. However, before this can be done, some changes and improvements will be made. Four new boilers will be substituted for those now in use. The Corliss engine will be overhauled, and all the present preparatory machinery, including the cards, will be taken out and new and improved substituted. The Westinghouse engine will be sold.

The main factory building is 215 feet long by 63 feet wide, and is equipped with 7,000 spindles. The factory lands include 15 ½ acres, on which are located 25 tenement homes. The property, having sold for only $31,000, is considered a great bargain.

Mayor W.C. Hutchison seated, left, and his associates running the City of Rock Hill. Courtesy of the Hutchison Group – 2020

The RH Herald of Aug. 12, 1899 reported – “The stock in the new Crescent Cotton Mills has been subscribed in the full amount of $50,000. Directors elected were: A.H. White, D. Hutchison, R.L. Kerr, and W.C. Hutchison. Mr. Kerr was elected Pres. and W.C. Hutchison, Treasurer.

The Herald reported on Oct. 4, 1899 – “Pres. R.L. Kerr of the Crescent Mill is making improvements. The old boiler house has been torn down and another will be erected in its place. The tenement houses are being renovated and they contemplate erecting 14 additional houses. A new street has been run through the premises for the convenience of the operatives. ” On Nov. 8 reported expansions to the mill village are completed the population of the village will be around 300.

The Herald reported on Nov. 8, 1899 – “The house to the rear of the White Memorial Church was bought by R.L. Kerr, Pres. of the Crescent Cotton Mill for $130., the house will be moved to the mill grounds and two rooms will be added.”

The Herald reported on Dec. 28, 1899 – “The boilers were fired yesterday at the Crescent Mill and for the first time in a year the familiar noon whistle of the old mill was heard in our city. Operations will begin soon.”

The Rock Hill Herald reported on June 2, 1900 – “Mr. H.F. Moody, who has been Supt. of the Crescent Mill in Rock Hill, will go to Greer where he will be Supt. of the Victor Mill.”

The Herald reported on Sept. 8, 1900 – “Judge Gage has appointed Capt. A.E. Smith as temporary receiver of the Cresent Cotton Mill. Mr. R. Lee Kerr has been president of the mill receivership is now requested because the company has failed to pay interest on the bonds it has issued.”

The Herald reported on Sept. 29, 1900 – “The Cresent Mill, after operating for two weeks under Mr. Smith as receiver, will be closed down this afternoon, with no prospect of a resumption of work.”

On Dec. 5, 1900, the Herald reported that “Mr. A.E. Smith receiver of the Crescent Cotton Mill, has advertised that it would be sold on Dec. 31. The property includes 8.5 acres, the mill buildings, and 24 tenement houses. The proposed price is $25,000.”

The Herald reported on Feb. 13, 1901 – “The purchasers of the Crescent Cotton Mill paid $34,965.87 for the mill. The deed was made to S.I. Cohen, Trustee. Mr. Sam Friedheim is one of the interested parties and stated that they will apply for a charger soon to organize a new company to operate the mill.”

The Herald contained and ad on March 6, 1901 – The real estate firm of J.E. Poag offering for sale, 18 houses and lots on White, Laurel, Peachtree and Wilson Street. (R&R believes these lots were part of the Crescent Mill Village.)

On March 13, 1901 the Herald reported, “The Chicora Cotton Mill has been organized and operations will begin within 90 days at the former Crescent Mill. Mr. W.D. Neal of Greensboro has been employed as the Supt. and will move to Rock Hill next week. The officers are: Isaac C. Cohen of Charleston – r. and Treasurer, Samuel Friedheim of Rock Hill – Sec., and Directors are: Mr. Cohen, Mr. Frieheim and F.LO. O’Neall, Nathaniel Israel of Charleston and J.W. Lindau of Greensboro. Separately from the sale of the mill Major A.H. White acquired three thousand five hundred and thirty six spindles from the old mill which he will sell to the Concord Mill. The new Chicoa Mill will have all new spindles and machinery.”

The Herald on March 30, 1901 contained a legal ad announcing the meeting of the stockholders of Chicora Cotton Mills to be held April 9th at the office of the Charleston Savings Institute at 24 Broad Street. The board plans to issue bonds of $60,000. Isaac S. Cohen, Pres. and Samuel Friedheim, Sec.”

The Herald reported on May 8, 1901 – “That the whistle of the Chicora Cotton Mill was heard Monday at noon, the first in many months. The machinery is now being readied for resumption of operations.”

The Herald reported on June 8, 1901 – “The Chicora Cotton Mill is waiting on new machinery and improvements have been made to the interior arrangement of the mill. The company is building a mixing room and a waste and press room.”

The Rock Hill Journal reported on June 12, 1901 – “That the Chicora Cotton Mill are having their tenant houses repainted.”

The Herald reported on Aug 11, 1901 – “That the new machinery has been installed in the Chicora Cotton Mill and operations will resume the first Monday in September. It includes six thousand modern spindles increasing the total to 11,400 spindles. Also included is a blower system to carry the cotton from the mixing room to the picker room and an automatic sprinkler system. When it opens, Rock Hill will have five factories in operation for the first time in five years.”

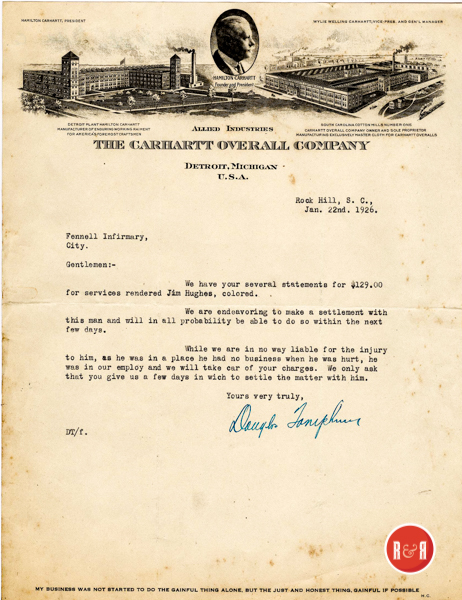

The Herald reported on Oct. 2, 1901 – “Johnnie McDonald, a boy of 11 years old, met a very serious accident at the mill last Saturday. While at work, his left arm was caught in the breaker between the roller and lap pin in the loom and was badly mashed from the wrist to the shoulder. The little sufferer was waited on by Dr. Hunter, who dressed his wounds. While the hurt is very serious and painful, amputation may not be necessary.”

The Herald reported on Sept. 3, 1902 – “There have been major changes at the Chicora Cotton Mill. Most of the leadership has resigned, including W.D. Neal, Supt., L.S. Neal, spinner, W.L. Neal – warper, Will Neal – Asst. warper, W.R. Long – engineer, and Mr. Reid the bookkeeper. New officers are: C.B. Haynes, Supt., Mr. Knight – overseer of carding and spinner, and George Scott of Concord, N.C., engineer.”

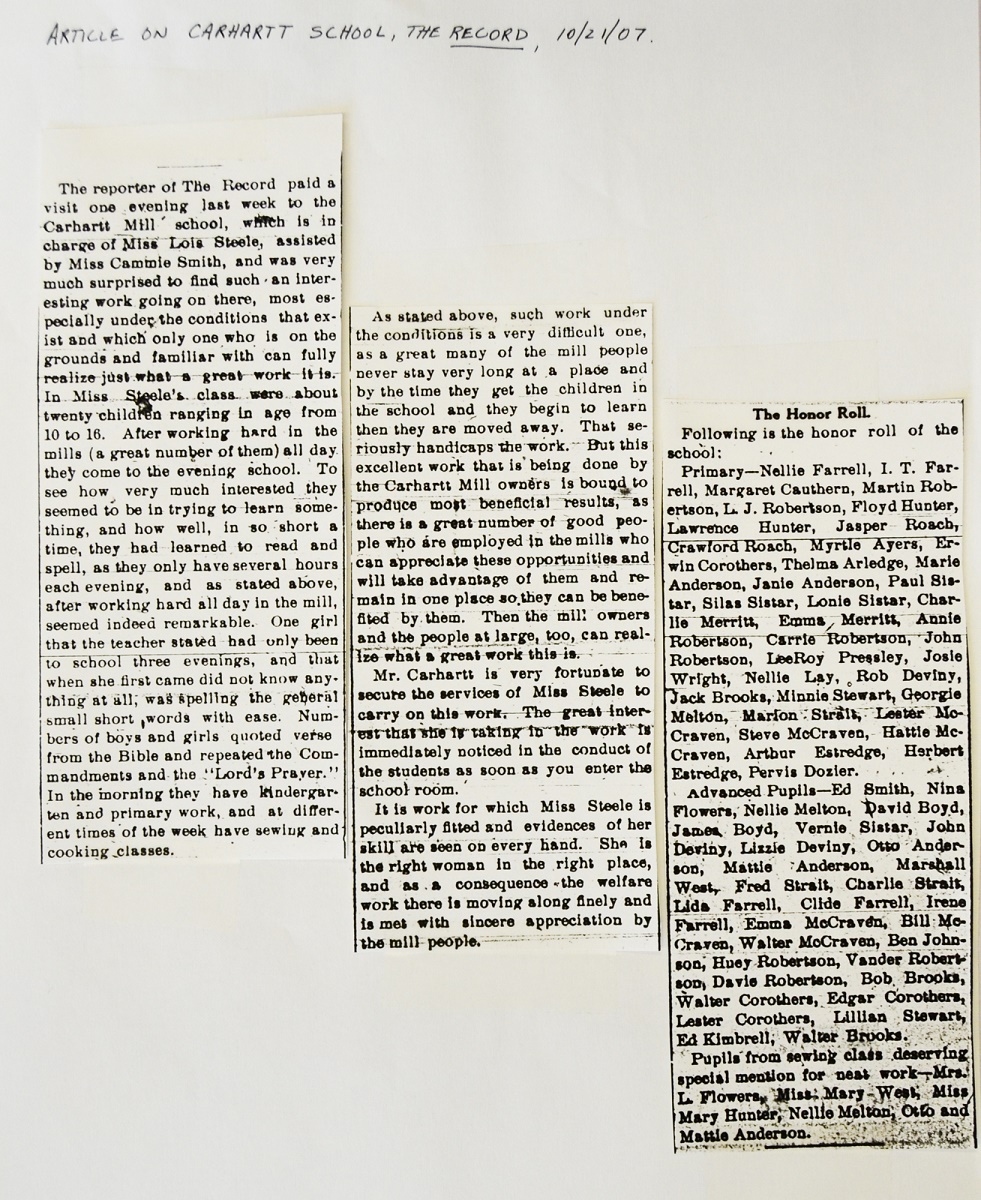

The SC Architects: 1885-1935 Wells & Dalton, 1992 attributed this building (a school for the Carhartt Cotton Mills) to architect Nat Gaillard Walker in 1909.

The Herald reported on Aug 11, 1901 – “That the new machinery has been installed in the Chicora Cotton Mill and operations will resume the first Monday in September. It includes six thousand modern spindles increasing the total to 11,400 spindles. Also included is a blower system to carry the cotton from the mixing room to the picker room and an automatic sprinkler system. When it opens, Rock Hill will have five factories in operation for the first time in five years.”

The Herald reported on Oct. 2, 1901 – “Johnnie McDonald, a boy of 11 years old, met a very serious accident at the mill last Saturday. While at work, his left arm was caught in the breaker between the roller and lap pin in the loom and was badly mashed from the wrist to the shoulder. The little sufferer was waited on by Dr. Hunter, who dressed his wounds. While the hurt is very serious and painful, amputation may not be necessary.”

The Herald reported on Feb. 4, 1903 – “Additional spindles have recently been placed in the Chicora Cotton Mill and several other changes have been made.”

The Herald on April 8, 1903 reported, “The act to prevent children under the age of 12 from working in the cotton mills will become law on the first of May.”

The Herald reported on May 9, 1903 – “An addition has been made to the Chicora Cotton Mill in the form of a dye house. ”

The Herald reported on June 27, 1903 – “The piston wrist on the engine of the Chicora Cotton Mill broke on Thursday and the machinery came to a stand still. Repairs are now being made, and it is hoped operations can be resumed Monday morning.”

The Rock Hill Herald reported on Oct. 5, 1915 – “Manager Henderson of the Hamilton Carhartt Mill stated Monday that a grinding mill was being installed to process vegetable Indigo here. The indigo is being shipped to this country from India and other places and it will take the place of the dye stuffs formerly shipped from German. Like another of big mills the local plant is getting ready to put the indigo cakes in usable condition.” R&R Note: This appears the origins of Carhartt clothing beginning to be marketed – sold in tan rather than their original blue colors.

The Rock Hill Herald reported on April 21, 1916 – “The German government has agreed to permit the exportation of 15,000 tons of dye stuffs to the U.S., the lack of which has seriously affected American textile manufacturers. To receive the products the U.S. must agree not to resend them to Britain.” Later on April 29th, the H. Carhartt Mills at Rock Hill have posted notice of a 5% advance in wages throughout all departments to take affect on May 1st.”

On April 22, 1916 the Herald reported – “Water and plumbing fixtures will be placed in 31 houses of operatives in the Carhartt Mill village, which is nearly the entire number of houses in the village. The contract for the work has been placed with L.F. Waldrop.”

The Rock Hill Cotton Factory, built in 1881, is significant for its leading role in the development of the textile industry in Rock Hill and for the major economic impact which this industry had on the town. The factory is also significant as an excellent example of an early textile building and of an architectural form that was repeated many times by later mills. As the cotton industry expanded in the 1870s, many communities in the Piedmont looked to financial investments and technology from New England to develop cotton manufacturing. An

aggressive business community in Rock Hill set out to supply the necessary capital and labor locally. The investors recruited Captain A. D. Holler to build the mill. He used the Camperdown Mill in Greenville as a model for the new Rock Hill mill. Opening in 1881, the mill became the first steam-driven textile mill in South Carolina, and was the first mill in Rock Hill. Later, as electricity became available from the pioneering hydroelectric development of the Catawba River, the mill was converted. A number of additions have been made to the building. Listed in the National Register June 10, 1992. Boundary increase March 6, 2008. [Courtesy of the S.C. Dept. of Archives and History]

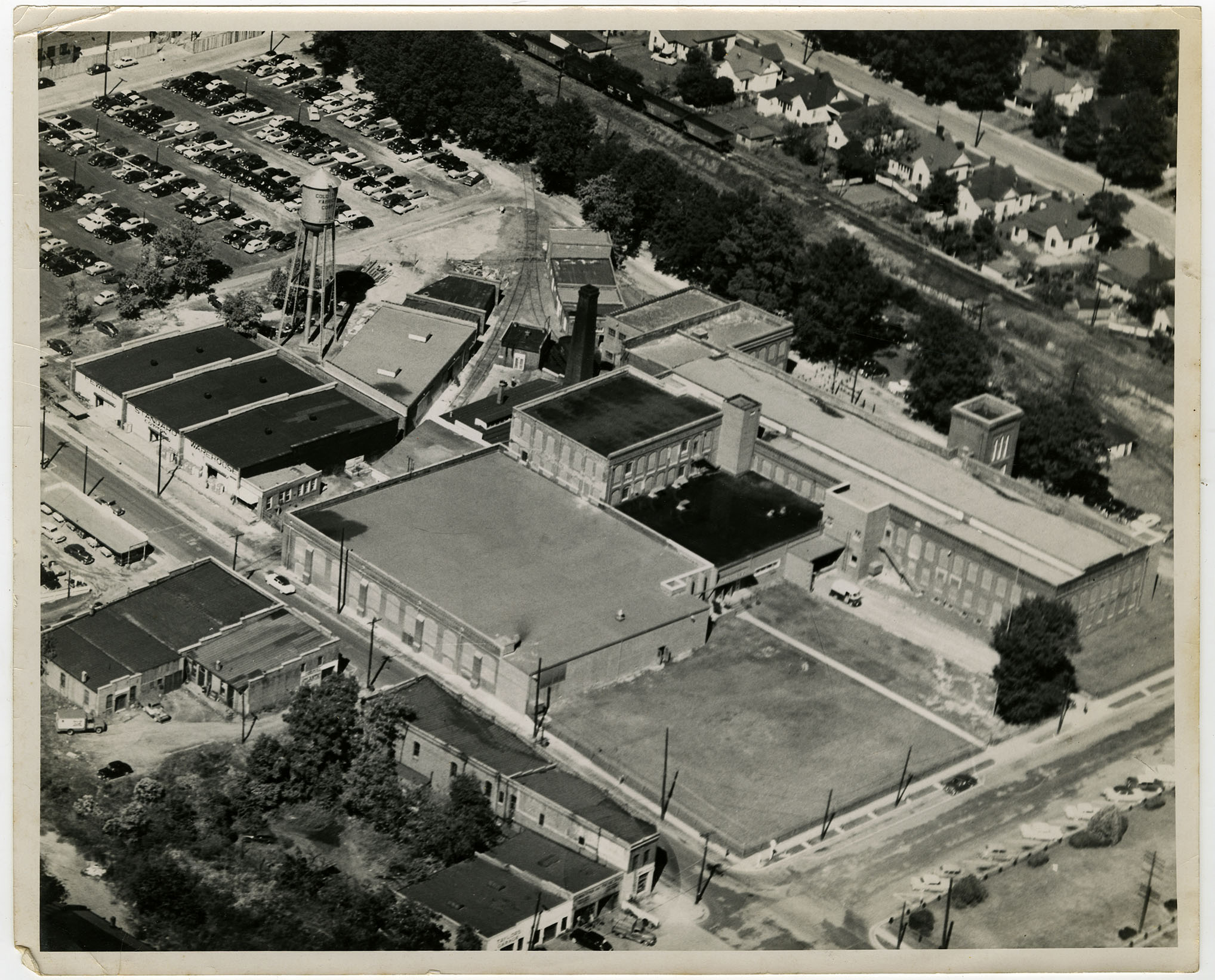

Image of the mill and Supt.’s home facing Chatham Avenue in 1927.

The mill was constructed by Rock Hill contractor A.D. Holler. The Charleston News and Courier reported on June 7, 1890 – “This factory was the 4th to be operated by steam power in S.C. Furthermore, it has about 8,000 spindles and annually consumes about 3,000 bales of cotton. The annual output is about 900,000 lbs of yarn. The officers are A.E. Hutchison, Pres., D. Hutchison, Sec. – Treasurer and directors: A.E. Hutchison, W.L. Roddey, J.S. White, J.R. London, A.H. White, John Gill of Baltimore, and F.J. Pelzer of Charleston. The factory operatives are comfortably quartered in neat cottages around the factory. Mr. J.R. Neesler is the Supt. of the factory.”

ROCK HILL COTTON FACTORY ARTICLE: Following the Civil War and reconstruction, business leaders in the South began to discuss ways of improving the devastated economy of the region. Cotton continued to be the principal crop. The raw cotton was shipped to New England where it was processed into finished products. Several leaders, especially newspaper editors in Atlanta and Charlotte, began to discuss the “New South,” an area which would not only grow the crops, but capture the full value by processing those crops, thereby expanding and diversifying the economy of the South.

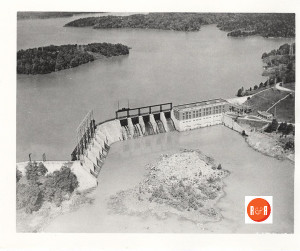

The creation of Lake Wylie was the brainchild of Dr. Gill Wylie, M.D., a New York physician with close kinships to many of Rock Hill’s early entrepreneurs. Production of hydroelectric power was important in the development of Rock Hill’s industrial expansion. Courtesy of the Jack Tucker Photo Collection – HRH.

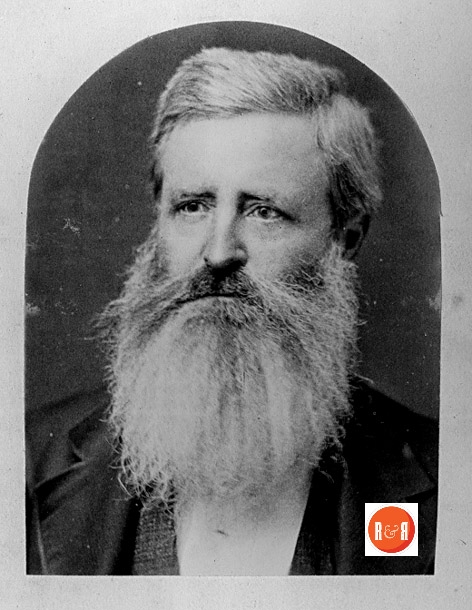

Textile mills had existed in South Carolina since the early 1800s, such as the mill at Graniteville, the Saluda River factory near Columbia, and a mill at Great Falls. The new mills were envisioned on a much larger scale. One of the first was the Camperdown Mill (1875) in Greenville, which used the water power of the Reedy River. The idea of the new South and the potential for mills in the cotton fields appealed to leaders in Rock Hill. James M. Ivy, the leading cotton broker in Rock Hill, and Adolphus Eugene Hutchison, a local merchant and farmer, began to raise funds for a new mill in Rock Hill. Other investors included Andrew Hutchison White, Hutchison’s nephew and cotton farmer, William Lyle Roddey, leading Rock Hill merchant, William Barron Fewell, physician, John Rutherford London, merchant, and Allen Jones, a banker. These investors also secured funds from other stockholders from outside Rock Hill. The Rock Hill Cotton Factory was incorporated in March 1880 with the issue of 1,000 shares of stock valued at $100 each.

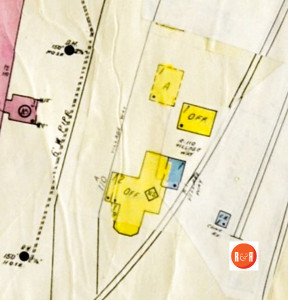

Sanborn Insurance Map of the subject (Supt.,’s Home), 1926 – 1959. Courtesy of the Galloway Map Collection.

Adolphus Hutchison was the largest shareholder and became President of the company. The group secured contractors A. D. Holler and R. H. Morse to build the structure. They traveled to Greenville and took measurements of the Camperdown Mill to use as a guide. Construction began in April 1880 on land purchased from the White family near downtown Rock Hill. The site had the advantage of being on the Charlotte, Columbia & Augusta Railroad and having good accessibility to local roads. The site is now at the corner of West White Street and Chatham Avenue. One disadvantage was that there was no easy source of water power at the site. This problem was solved by designing the mill to run steam power, the first such mill in South Carolina. Wells on the property provided water which fed a 200-horsepower steam engine.

The Rock Hill Cotton Factory began operating in May 1881 with 3,000 spindles. The original employment was 40 laborers, most of whom were women and children. From this modest beginning, a textile industry grew in Rock Hill over the several decades which would employ thousands and serve as the basis of the local economy for generations. A. D. Holler would serve as contractor for many of the mills and other buildings in the rapidly growing city. Largely because of the influence of the textile mills, Rock Hill’s population increased from 809 in 1880 to 5,400 in 1890.

Within a year, the Cotton Factory had expanded to 100 employees and had purchased additional land from the Steele and Ratterree families for the construction of houses for its workers, the beginning of the mill village system in Rock Hill. New investors joined the board of directors over the next few years. By 1895, the Cotton factory consumed about 2,500 bales of cotton each year and produced yarn and was weaving cloth, including shirting, sheeting, drills, and cotton rope. By this time, employment had increased to 175 workers.

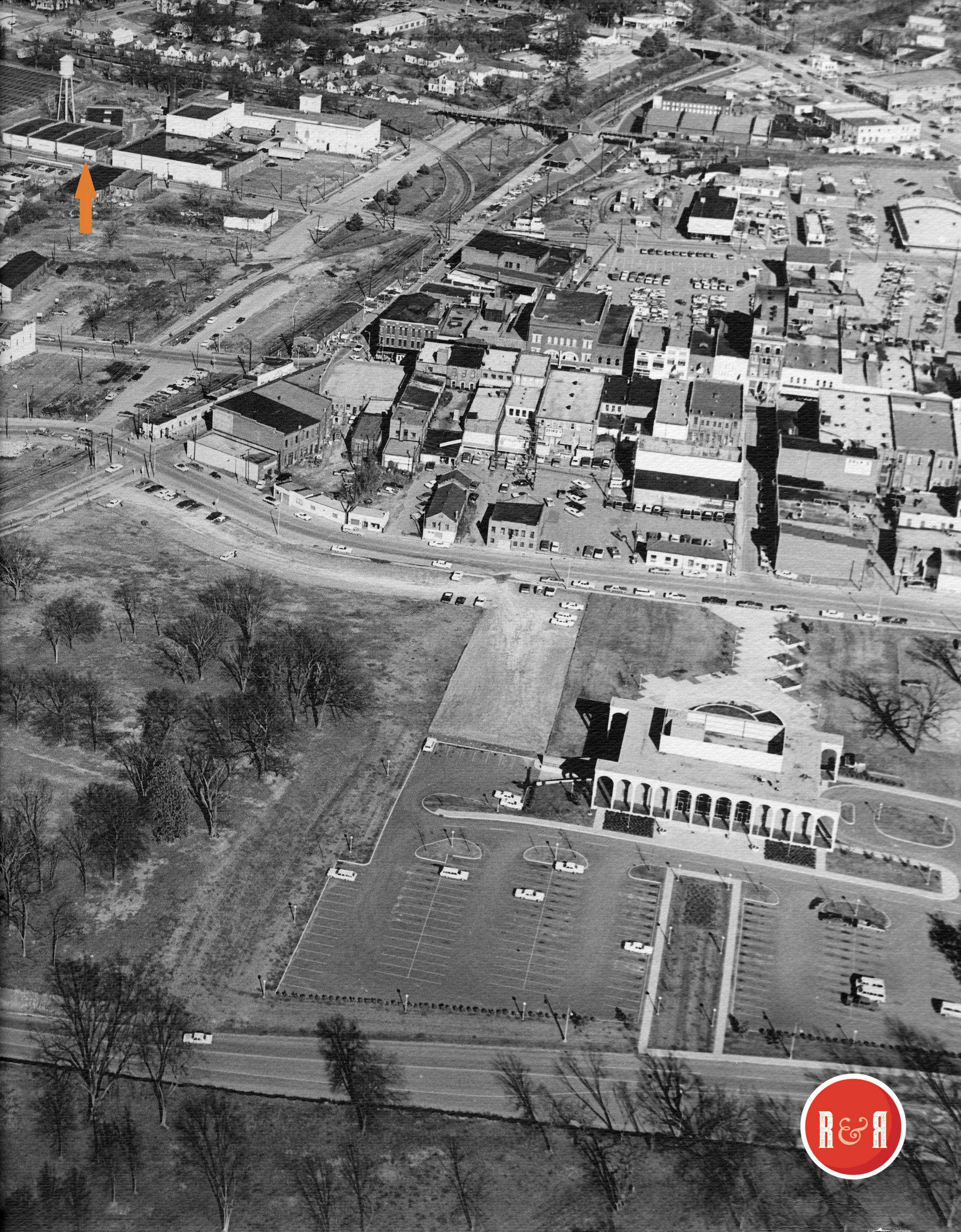

The textile industry was subject to various economic disruptions, including failed cotton crops, banking failures, and national recessions. In 1898, the Cotton Factory faced a crisis and ceased operations. Within a year, the mill had been purchased and reorganized by W. C. Hutchison and A. H. White under the name Crescent Cotton Mills. This was the first of a number of reorganizations and changes of ownership and name for the factory. In 1900 it was purchased by a group which included Rock Hill merchant Samuel Friedheim. In 1904, the factory was sold to Southern Textile Company, a New York textile operator. It was renamed the Chicora Mill. Within a year, this company had declared bankruptcy, and in 1905, the mill was purchased by Hamilton Carhartt. Carhartt was a Detroit textile leader who was one of the world’s largest manufacturers of overalls and work gloves. He became a frequent visitor to Rock Hill as he invested in the mill and expanded its operations. It became known as the Hamilton Carhartt Cotton Mill No. 1. He converted the mill from steam power to electrical power, using electricity from the new Lake Wylie Dam. He added a three-story annex and dyeing room at the downtown mil and built a second mill and village near the Catawba River which became known as Red River. Nearby, Carhartt built a home for himself overlooking the Catawba River for use on his trips to the area, and developed recreational facilities for his workers. He began manufacturing denim, with overalls produced in Rock Hill becoming well known throughout the world. During World War I, the business prospered as he sold goods to the military and the booming war time work force.

overalls produced in Rock Hill becoming well known throughout the world. During World War I, the business prospered as he sold goods to the military and the booming war time work force.

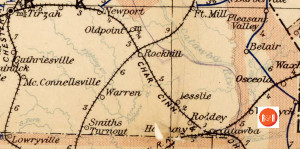

Postal map showing Rock Hill as a transportation hub on two railroads in 1896. Courtesy of the Un. of NC

Carhartt’s expansion led to debt which proved to be a problem when a recession hit in the early 1920s. Both the Rock Hill mills closed in 1921. In 1925, the Mill No. 1 (the original Rock Hill Cotton Factory with expansions) was turned over the John H. Cutter, a broker and real estate agent in Charlotte who held much of Carhartt’s debt. It was reorganized as Cutter Manufacturing Company, which produced denim, ticking, and other goods. It operated through the Great Depression, and had strong business during World War II, supplying fabrics for the military. After the war, the military contracts ended and Cutter was unable to secure new contracts. The mill was sold again in 1946, this time to M. C. Goldberg of Philadelphia, who operated the mill as Gold-Tex Fabrics. Major modernization was undertaken in the mid-1950s, but the mill closed in 1963 during a recession. In 1965 Sol and Edward Aberman purchased the property and converted it to the production of double-knit fabrics. This market, which had proved promising, soon declined, and the mill again closed in 1967. In 1968, the plant was purchased by the Ostrow Textile Company from Charlotte, which moved its operations to the site. Part of the mill was used for warehousing and a section became a retail business known as Plej’s Textile Mill Outlet. The Ostrow operation closed in 2000. Soon after, the Cotton factory was acquired by the Rock Hill Economic Development Corporation which marketed the site as part of its downtown redevelopment efforts. In 2006, it was purchased by Williams & Fudge, a Rock Hill based student loan collection agency. The mill buildings were completely renovated into modern office and retail space.

In recognition of its importance as Rock Hill’s first textile mill, the building was placed on the National Register of Historic Places in 1992, and a South Carolina Historical Marker was dedicated in 2007.

Information for this article was provided via the publication “A History of the Rock Hill Cotton Factory” written by Michael C. Scoggins of the York County Culture & Heritage Museums and submitted by Paul M. Gettys to R&R on 4.20.14.

Also see the MORE INFORMATION / HISTORY link, found below the picture column, for details on Mr. Ivy, a major contributor to Rock Hill’s success stories, as well as a map showing the extensive Carhartt property which later became central in attracting Celanese to Rock Hill. Also click here “Sanborn Map #6” to see further changes to the mill’s layout.

Rock Hill Cotton Factory

The Rock Hill Record reported on Oct. 15, 1908 – “Work on the addition to the Carhartt Mills is progressing. The foundation is laid and walls are partially erected. the property was formerly considered an eye sore by some, but now has an attractive appearance.”

The RH Record reported on Feb. 15, 1909 – “Mr. Carhartt has let the contracts for extensive work on his mill to include a new building 140-35 ft, a new monitor on the mill, a four and one-half ft wall around the entire building, and sixteen new tenant houses to be erected on the property in front of the Rock Hill Buggy Co plant, which area he recently purchased for $8,000.”

The Rock Hill Record of March 29, 1909 – “Mr. Carhartt’s mill is being improved and work on the front of the mill is completed. Mr. Carhartt settlement, above the Buggy Company will be a beauty. Mr. A.D. Holler has the contract for the addition to the Mill.”

The Rock Hill Herald reported on Oct. 14, 1910 – “The Carhartt Mill will close on Saturday for a period of 30-60 days in order to make changes. All the machinery on the second floor will be moved to the first floor and some new machinery added.”

From the Rock Hill Record of March 27, 1913 – “Love & Owens were awarded another contract yesterday by Hamilton Carhartt to add another story to the addition now being built to the Carhartt mill property, which is to provide more room for the manufacture of overalls. The first contract to Love & Owens called for one additional story only. When the job is completed it will make quite a showing.”

The Herald reported on March 17, 1925 – “That the Carhartt Mills plans to build sixteen new dwellings on various streets of the mill village at a cost of $3,900. and seven garages at a total cost of $1,400.”

The Herald reported on Aug. 31, 1925 – “That the Catawba River Golf Club was organized about eight years ago and received a lease from Hamilton Carhartt for property is uses near the Catawba Bridge. The lease will expire in a year or two.”

The Herald reported on June 18, 1925 – “Within recent weeks, practically all the cotton mills in Rock Hill has suspended or reduced work, but the mill workers are optimistic on the outlook. Aragon and Arcade are both shirting manufacturers and are on full schedules. Wymojo Mill is on a three day a week schedule. Industrial Mill is on a four day week schedule, Carhartt on a three day schedule after suspending operations. The gingham manufacturing is running full-time this week but the schedule is indefinite. Harris Mill (Victoria #2) runs with Victoria’s schedule and Helen Mill runs with Wymojo.”

The Herald reported on Oct. 2, 1925 – “Hamilton Carhartt Cotton Mill #2 on the river has been sold to a corporation of local investors. C.L. Cobb represents the buyers. The plan is to erect thirty new homes and have day and night shifts. It will employ between 200- 300 people. York Wilson is President. The mill had suspended operation over a year ago. The Carhartt Company is also selling its mill in Elberton, Ga., but trying to maintain the number #1 mill in Rock Hill, which produces denim.”

The Herald reported on May 20, 1931 – “The Catawba River Golf Club had a tournament yesterday. R.H. Jones of Rock Hill took first place, J.L. Spratt of Fort Mill, took second place and Ed Allen of Rock Hill took third place. The group had a picnic supper in the grove adjoining the club house. W.B. Avery, the Manager and Treasurer reported the finances were in good condition. The matter of buying a permanent site for the club was discussed.”

For additional information and pages on the mill click on RH Cotton Factory #2

Click HOME to return to the numbered site tour of Rock Hill’s downtown.

Stay Connected

Explore history, houses, and stories across S.C. Your membership provides you with updates on regional topics, information on historic research, preservation, and monthly feature articles. But remember R&R wants to hear from you and assist in preserving your own family genealogy and memorabilia.

Visit the Southern Queries – Forum to receive assistance in answering questions, discuss genealogy, and enjoy exploring preservation topics with other members. Also listed are several history and genealogical researchers for hire.

User comments welcome — post at the bottom of this page.

Please enjoy this structure and all those listed in Roots and Recall. But remember each is private property. So view them from a distance or from a public area such as the sidewalk or public road.

Do you have information to share and preserve? Family, school, church, or other older photos and stories are welcome. Send them digitally through the “Share Your Story” link, so they too might be posted on Roots and Recall.

Thanks!

User comments always welcome - please post at the bottom of this page.

Share Your Comments & Feedback: